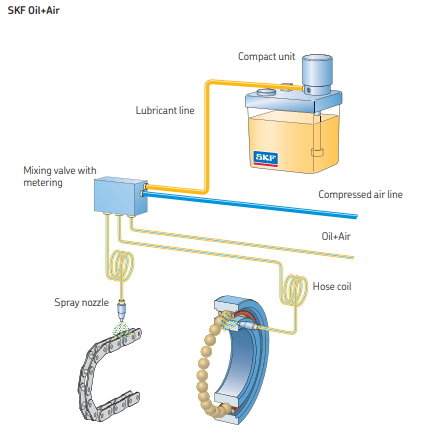

Oil and Air Lubrication Systems

HES Lubemec offers extensive knowledge and technical advice on all types of centralised (or automatic) lubrication system, including oil and air systems.

Air/Oil systems are used predominantly for high-speed bearings, of the kind used in machine tool spindles, although they may also be used for chain lubrication and other applications where very small quantities of oil are required.

The systems incorporate an oil pump and single-line distributors (or progressive distributors) injecting oil into a mixing valve. The oil supply is picked in very small droplets by the air flow, and transported to the lubrication point with suitable tubing. The air is very low pressure, therefore no misting occurs, and oil deposited can be up to 90% less than conventional misting systems.

When used for high-speed bearings, the air flow assists in cooling the bearing, and also creates a low positive pressure in the bearing housing providing protection from outside contamination.

Air/Oil systems are available tailor-made for each application and may incorporate accessories including air pressure monitoring, and flow monitoring using SKF oil streak sensor technology.

For more information do not hesitate to contact our specialists today on 01452 733 104 or email enquiries@grouphes.com

Catalogues:

Control Units for Oil+Air Lubrication