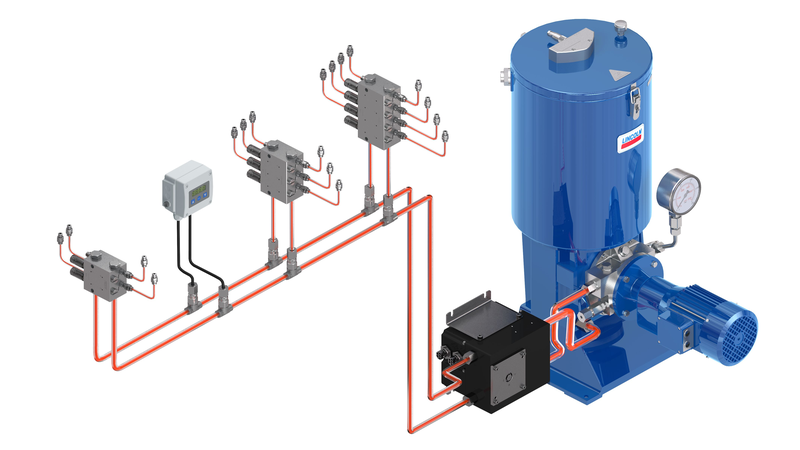

Dual-line Lubrication Systems

Dual-line lubrication systems are suitable for medium or large machines and are the ideal choice for applications with long line lengths and harsh conditions.

HES Lubemec offers a wide range of electric or pneumatic pump options, with reservoir sizes up to 60 Kg, or for mounting in standard grease kegs.

The system typically comprises the pump, dual line distribution valves, change-over valve, pressure switches and controller. The pump feeds grease to a changeover valve, which has 2 outlets – which are pressurised in turn. Dual main lines (up to 38mm diameter) run the length of the application, with dual branch lines tees off to the various distributors feeding the lubrication points.

The distributors are available in a variety of types, output volumes and number of outputs depending on the application.

As the first line is pressurised, the second line is vented, causing the pistons in the distributors to move in one direction – dispensing grease to the lubrication points.

When the set pressure is attained, the changeover valve reverses the process, relieving the first line and pressurising the second line – moving the pistons in the distributors in the opposite direction again dispensing grease to the lubrication points.

The system controller monitors this cycle, and when complete will revert to the pre-set delay time.

Typical applications for HES Lubemec Dual Line Systems are pulp and paper mills, cement factories, brick manufacturing plant, quarries etc.

Dual-line lubrication system - Click Here

Dual-line accessories - Click Here

For more information on dual-line lubrication systems please call the experts today on 01452 733 104 or email enquiries@grouphes.com

Catalogues: